|

Surface preparation

|

Wood surface must be clean, dry and frost-free (moisture content max. 18%).

Osmo Oil Stain is ready to use. Do not thin. Stir well before use.

Clean old microporous stains thoroughly. Old paints and lacquers must be completely removed. As a general rule, wear a dust mask during sanding works. Fill small cracks, larger joints or holes in wood (with Osmo Wood Filler).

Sand wood surfaces carefully. Begin with coarse sandpaper – final sanding work for flooring grit P120-150, for furniture girt P220-240. Before oiling the surface, remove sanding dust with a broom or vacuum.

The finished surface is influenced by several factors, including the condition of the wood. Therefore, a trial application is always required, especially for unfamiliar surfaces.

|

|

Method of application

|

Transparent colour: with Osmo Floor Brush, Osmo Microfibre Roller, Oil Finish Applicator Fleece (Hand Pad Holder) or Double Blade Scraper, apply very thinly and evenly to the clean and dry wood along the wood grain and rub into the wood with a white pad. For larger areas use the Osmo Floor-X- center / white pad for an even colour tone. Allow to dry for approx. 12 hours under good ventilation.

Intensive colour: if a stronger colour is desired, apply thinly along the wood grain with Osmo Microfibre Roller or Floor Brush, and spread well. Please note, Oil stain will penetrate quite quickly therefore on thirsty woods a hand application may appear patchy. Trial applications highly recommended first. For best results, rub in to the wood with white pad.

Tip: With an unused Osmo Microfibre Roller, any brushstrokes can be removed within 30 minutes after application. Ventilate well while drying. If an even more intensive colour is desired, apply a second coat with Osmo Double Blade Scraper, Osmo Microfibre Roller or Floor Brush, and rub into the wood with a white pad. Ensure first coat of Osmo Oil Stain has fully dried before rubbing in second coat with white pad.

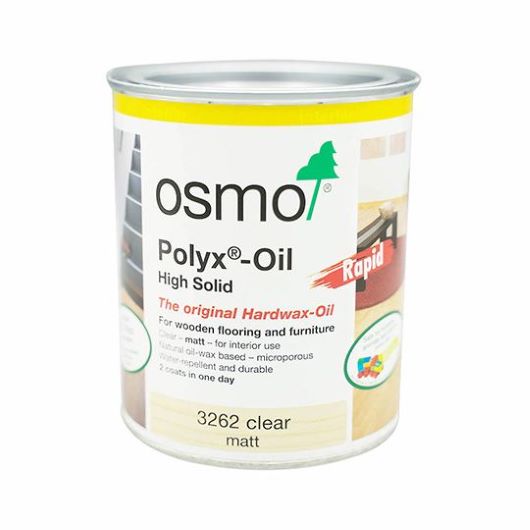

After thoroughly drying, a top coat should be carried out with a clear Osmo Polyx®-Oil.

For smaller areas, e.g. furniture, Osmo Oil Stain can be applied with a lint-free cloth.

|

|

Note

|

Applications with the Hardener for Oil Stain 6631 as drying accelerator are also possible as an option.

Please observe the instructions for a correct application.

For dark woods and hardwoods rich in extractives (e.g. Wenge, Merbau, Jatoba etc.), we recommend using Osmo Wood Wax Finish Clear Extra Thin or Osmo Polyx®-Oil 2K Pure. A trial application is recommended.

Colour tone 3501 White: An intensive white surface is not recommended for flooring because it is more sensitive and prone to natural yellowing. As a top coat for such surfaces, the pigmented Polyx®-Oils 3040 or 3240 (White transparent) is recommended.

Colour tone 3519 Natural: A thin coat is recommended either with Osmo Microfibre Roller or Floor Brush.

After drying, a coat with a clear Osmo Polyx®-Oil should be carried out. The natural colour tone of wood is preserved – it does not enhance the tone of wood, no permanent wet effect. This finish leaves white streaks on red/dark wood species.

Using general or multi-purpose cleaners will increase the frequency of maintenance and recoating. Allow finish to fully cure before heavy usage.

|

|

Color

|

3501 White, 3512 Silver Grey, 3514 Graphite, 3519 Natural, 3564 Tobacco, 3590 Black

|